The primary function of a wire harness assembly is to solve issues within electrical systems related to electrical requirements and geometric limitations providing physical support for a grouping of cables and wires installed within space.

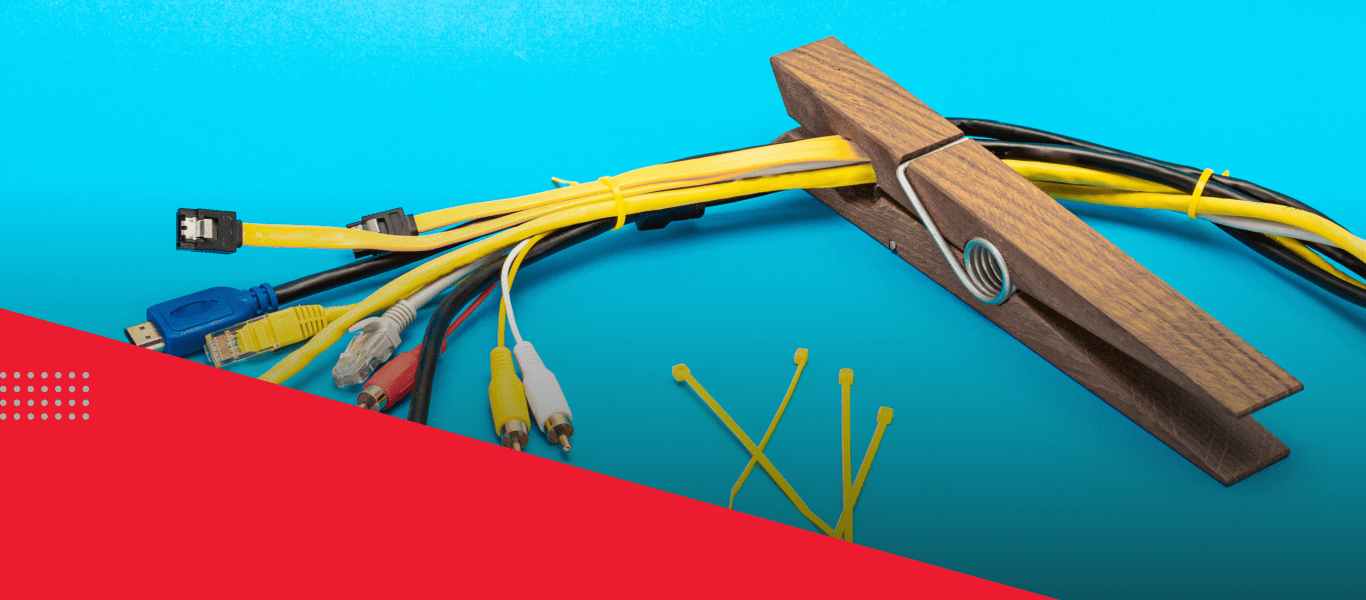

Sometimes called a cable or wiring loom, a harness assembly arranges groups of wires and/or cables into a single unit for protection and organization with various terminals and connectors attached, forming a shape or layout that routes connectors to the various connection points of an assembly.

A harness assembly typically uses sleeved wires and/or multi-conductor cables held together by ty wraps or tubing which protects and organizes the bundled wire/cables. Several applications require unique terminations like plug or socket arrangements attached to the wires. All wire harnesses are customized for their intended operating environment concerning the number of potential variables involved. An essential part of facilitating a quicker and easier installation is to maintain the required lengths and orientations of wires and cables. According to the specified application, its assemblies may include a multitude of cable or wire constructions, sizes, colors, and materials used.

A wire harness provides a low-cost electrical solution designed to organize electrical wiring systems and requires an eye for detail and expert solutions. Typically used only for outdoor purposes - Wire harnesses are largely utilized only for organizational purposes in applications with less demanding requirements and minimal environmental risks.

The primary use of harness assemblies relates to efforts saving precious time in mass production where a machine or component assembly repetition is an essential part of unit manufacturing.

Expert SolidPro Engineers are adept in providing the below Wire Harness Engineering services

We can create parametrically the following

The Electrical harness flattening and drafting also can be done.

We can create 3D/2D harness drawing from the existing harness drawing

Every wire harness needs to align with the geometric and electrical requirements of the device or appliance for which it is used. Characteristically Wire harnesses are entirely separate pieces from the large, manufactured components that house them. This brings several benefits, which include

The manufacturing process starts with design and schematic development before moving to prototyping and finally to production. Precisely measured wire lengths are assembled by Operators to wire harnesses to drawn-out test boards. The board confirms that the designed terminal and connector housings suit the application being used and that cable ties and coverings are added for easy organization and transport.

Wire harness cable assembly is a multifaceted process. The complexity of the end product means that Automation plays an important role in all manufacturing processes, while many sub-steps of the assembly process are done by hand. The main steps of this process include

Solidpro is committed to providing cable and wire harness assemblies that meet or exceed the quality expectations of our customers. We provide evidence of our commitment by, ensuring that we provide our customers with only the highest-quality solutions. All our processes are subjected to rigorous testing that meets the strictest requirements set forth by the international ISO framework.

© 2026 Solidpro. Designed with passion @ Spidergems Softlabz